Safety

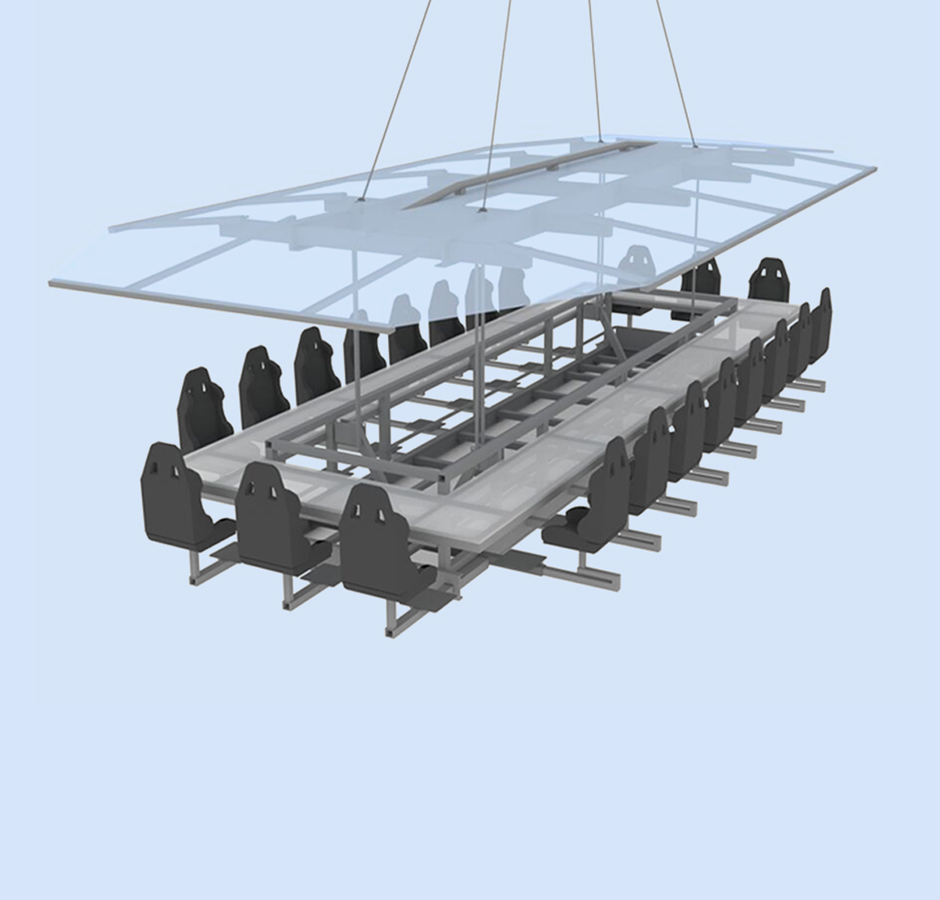

"The Sky Dining India structure’s entire length is 9 meters, with a width of 5 meters. It is suspended on 16 metal wire ropes, 8 below and 8 above the roof. Each Rope has safe load capacity of 4 ton, which means a single rope can carry the whole structure. That enables a weight capacity 8 times the safe load capacity. That’s how seriously Sky Dining India takes your safety.” “Sky Dining India has been conceptualised and designed according to ISO Standard. Platforms are built by the best team of engineers at Sky Dining India. From the seat belts to the type of crane used, has been scrutinized and carefully considered to ensure maximum safety for the clients and employees." "While seated you wear safety belts, standing presenter and crew are secured by safety harnesses all the time during the flight. A safety supervisor will brief you about all safety regulations prior to the flight and will be in constant communication with crane operator and ground crew so that he has a complete picture of the situation during the operation. "The organising company gives painstaking attention to every detail in order to maximise security and ensure that you always feel safe."